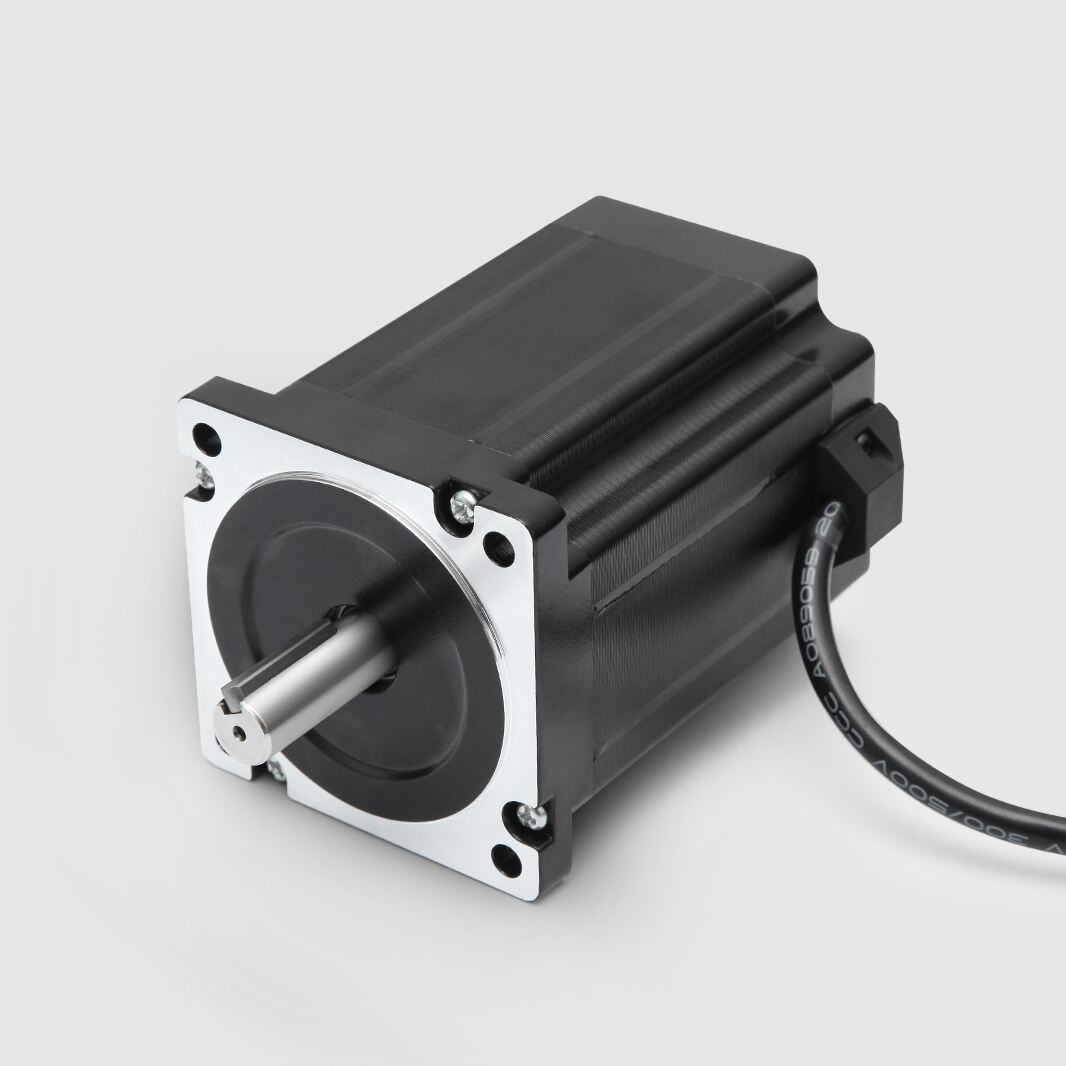

24 volt dc servo motor

The 24 volt DC servo motor is a precision electrical device designed to convert electrical energy into mechanical rotation with high accuracy and efficiency. Its main functions include precise positioning, speed control, and torque output, which are vital in a variety of industrial and commercial applications. Technological features of the 24 volt DC servo motor encompass a robust design with high torque capacity, low inertia, and excellent thermal characteristics, ensuring reliable performance even in harsh environments. This type of motor is typically equipped with feedback devices like encoders that provide real-time position and speed data, enabling closed-loop control for consistent and repeatable motion. Common applications range from robotics and automation systems to medical equipment and aerospace, where precision and reliability are paramount.