Onze DM860D is een hoogwaardige digitale stapper driver gebaseerd op DSP en PID besturingsalgoritme met microstep control technologie. De stappenmotoren aangedreven door DM860D kunnen met veel minder lawaai en veel minder trillingen werken dan andere motoren op de markt. De DM860D's hebben de eigenschap van minder lawaai, minder trillingen en minder verwarming. De spanning is DC24V~80V of AC20V~60V. Het is geschikt voor alle 2-fasen stappenmotoren met een stroom van minder dan 7,2 A. Er zijn 16 soorten micro-stappen van DM860D. Het maximum aantal stappen van DM860D is 51200 stappen/omwenteling (microstep is 1/256). Het stroombereik is 2,4A ~ 7,2A en de uitgangsstroom heeft 8 stalletjes. DM860D heeft automatische halfstroom, overspanning, onderspanning en overstroom bescherming functie. Onze DM860D-stapperdriver kan worden toegepast in een verscheidenheid aan kleine automatiseringsapparatuur en -instrumenten, zoals etiketteringsmachine, snijmachine, verpakkingsmachine, tekenmachine, gravureermachine, CNC-machine enzovoort.

1. Kenmerken

● Aanneming van 32-bit DSP, zuivere sinusgolf-onderdelingstechnologie

● Geruisloos, weinig trillingen en lage temperatuur

● Spanning 24-80VDC of 20-60VAC

● Met 8 stations uitslagstroominstelling, piekstroom 7,2A

● Met 16 kraampjes, micro-step onderverdeling

● Automatische halve stroom, zelftest, overspanning, onderspanning, overstroombescherming

● Interne optische isolatie, hoogste frequentiereactie 200KHZ.

● Geschikt voor stroombereik 2.4-7.2A 2-fase, 4-fase nema34 stappenmotor

2.Microstep Resolution Selection (De keuze van de microstep-resolutie)

Puls/REV | SW5 | SW6 | SW7 | SW8 |

Standaard | Aan | Aan | Aan | Aan |

800 | Afgeschakeld | Aan | Aan | Aan |

1600 | Aan | Afgeschakeld | Aan | Aan |

3200 | Afgeschakeld | Afgeschakeld | Aan | Aan |

6400 | Aan | Aan | Afgeschakeld | Aan |

12800 | Afgeschakeld | Aan | Afgeschakeld | Aan |

25600 | Aan | Afgeschakeld | Afgeschakeld | Aan |

51200 | Afgeschakeld | Afgeschakeld | Afgeschakeld | Aan |

1000 | Aan | Aan | Aan | Afgeschakeld |

2000 | Afgeschakeld | Aan | Aan | Afgeschakeld |

4000 | Aan | Afgeschakeld | Aan | Afgeschakeld |

5000 | Afgeschakeld | Afgeschakeld | Aan | Afgeschakeld |

8000 | Aan | Aan | Afgeschakeld | Afgeschakeld |

10000 | Afgeschakeld | Aan | Afgeschakeld | Afgeschakeld |

20000 | Aan | Afgeschakeld | Afgeschakeld | Afgeschakeld |

40000 | Afgeschakeld | Afgeschakeld | Afgeschakeld | Afgeschakeld |

Standaard: de puls kan worden aangepast aan de eisen van de klant.

3.Huidige instelling

REF | De hoogtepunt | SW1 | SW2 | SW3 |

2.00A | 2.40A | Aan | Aan | Aan |

2.57A | 3.08A | Afgeschakeld | Aan | Aan |

3.14A | 3.77A | Aan | Afgeschakeld | Aan |

3.71A | 4.45A | Afgeschakeld | Afgeschakeld | Aan |

4.28A | 5.14A | Aan | Aan | Afgeschakeld |

4.86A | 5.83A | Afgeschakeld | Aan | Afgeschakeld |

5.43A | 6.52A | Aan | Afgeschakeld | Afgeschakeld |

6.00A | 7.20A | Afgeschakeld | Afgeschakeld | Afgeschakeld |

Gebruikers kunnen de halfstroomfunctie van de stuurmachine instellen op SW4. "OFF" geeft aan dat de stilstandstroom is ingesteld op de helft van de dynamische stroom. "ON" geeft aan dat de stilstandstroom en de dynamische stroom hetzelfde zijn. De gebruiker kan SW4 instellen op "OFF" om de motor en de bestuurder te verwarmen en de betrouwbaarheid te verbeteren.

4.Beschrijving van de interface

Signal | Functie | Bedieningsinstructies |

Alarm/PWR | Lichten met indicator | Er zijn twee indicatorlichten. De energie-indicator is groen. Wanneer de stapper aandrijft, is het groene licht altijd aan. De foutindicator is rood, wanneer er een overspanning of overstroomfout is, zal het rode licht altijd branden; nadat de fout van de bestuurder is opgelost, zal het rode licht uitgaan als de stroom opnieuw wordt ingeschakeld. |

DIR-/DIR+ | Signalinterfaces | PUL+ en PUL- zijn de positieve en negatieve kant van het regelappulssignaal; DIR+ en DIR- zijn de positieve en negatieve kant van het richtingssignaal; ENA+ en ENA- zijn de positieve en negatieve kant van het activatiesignaal. |

PUL-/PUL+ | ||

ENA-/ENA+ | ||

A+ | Motorinterfaces | A+ en A- zijn verbonden met een fase-winding van de motor; B+ en B zijn verbonden met een andere fase-winding van de motor. Als je achteruit moet, kan een van de fase-opwikkelingen worden omgekeerd. |

- Ik ben... | ||

B+ | ||

B- | ||

+Vdc | Stroominterfaces | De stapperdriver gebruikt een gelijkstroomtoevoer. De aanbevolen bedrijfsspanning is 24VDC-80VDC en het stroomverbruik moet hoger zijn dan 350W. |

GND |

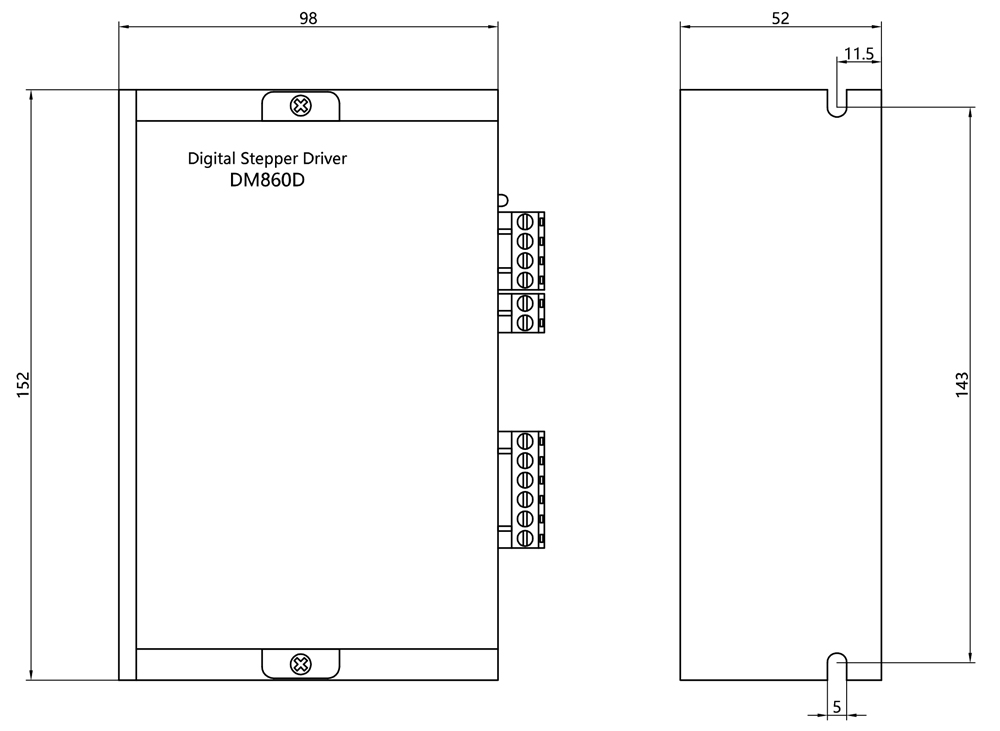

5.Algemene afmetingen

Copyright © Changzhou Jinsanshi Mechatronics Co., Ltd. Alle rechten voorbehouden. - Privacybeleid